How to update controller firmware with CNC USB

How to update controller firmware with PlanetCNC TNG

How to get and activate license

Essential

How to connect and configure controller and software

How to connect motor drivers

How set 'steps per unit' (SPU)

How set speed and acceleration

How set jogging

Basic

How to connect and set limit switches

How to configure homing procedure

How to configure motor soft limits

How to configure and use moveable sensor

How to configure and use fixed tool sensor

How to configure basic tool change procedure

How to configure and use tool table

How to configure gantry square procedure

Easy

How to use different machine profiles

How to customize state panel

How to customize toolbar buttons

How to customize wireless handwheel

How to edit built-in script files

How to install and configure Python

How to configure OpenCV as external camera

How to configure laser machine

How to configure automatic tool change (ATC)

How to configure and use tool table pockets

Advanced

Use 3D object visualization in TNG software

Expert

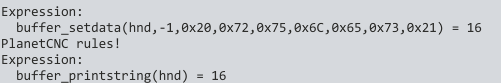

Use Expressions to command semaphore lights

Use Expressions and MODBUS to command relay boards

Use Expressions and MODBUS to command VFD